Stay up-to-date with all the latest news from Cadent and find out what's happening in your area.

Part of £91million programme to upgrade ageing gas mains across the East of England

14 October 2025

A project to upgrade one of the oldest sections of gas pipeline situated under the A405 in Watford, is set to begin on Monday 20 October.

13 October 2025

Charities, community centres and local businesses came together recently to discuss the pressing challenges facing people living in vulnerable situations across the East of England.

10 October 2025

Four weeks on from a third party damaging a gas main which runs under a field off Heywood Road, near Diss, work continues to repair the escape

10 October 2025

Road closure for three weeks, followed by two weeks of traffic lights

07 October 2025

Work to replace ageing gas pipes in Witham, Essex, is coming to an end with the project entering its final stages.

07 October 2025

A major milestone has been reached in a project that will keep tens of thousands of homes in Cumbria warm for decades.

29 September 2025

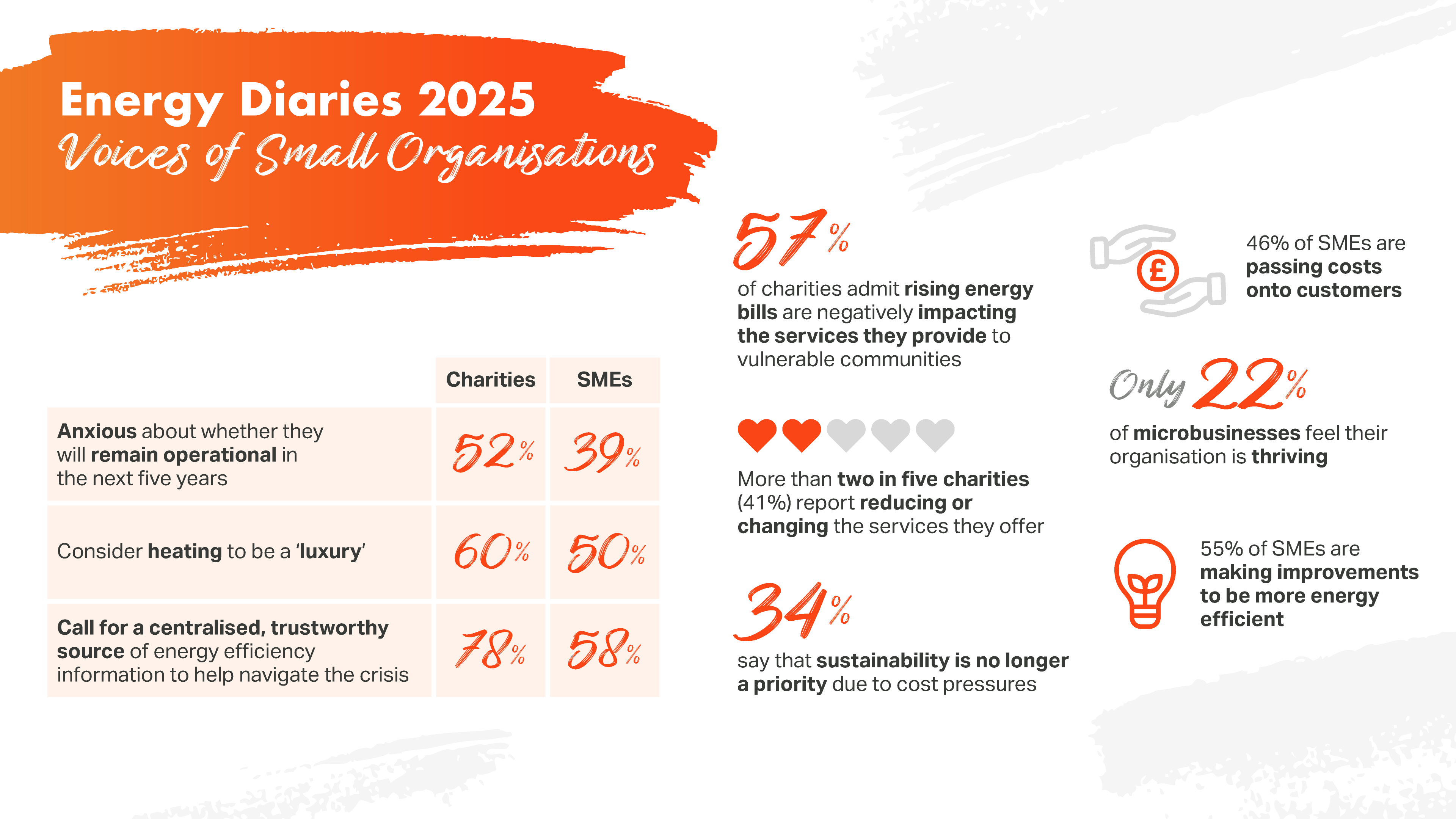

Cadent has collaborated with Energy Saving Trust to provide actionable energy-saving tips for businesses and organisations under pressure.

29 September 2025

Emergency repair work will start on Burlington Lane, Chiswick, from Sunday 28 September from 9pm for approximately one week.

26 September 2025

We received a call on Thursday 11 September reporting that one of our gas pipes in a field off Heywood Road, near Diss, had been damaged by a third party.

26 September 2025

The work will begin the afternoon of Saturday 27 September and is expected to be completed by Sunday 28 September.

26 September 2025

Emergency work is taking place to repair a gas main under one of the main routes into Boston, Lincolnshire.

19 September 2025

Opportunity for residents to learn more about essential gas work in Lower Nazeing

19 September 2025

We’re upgrading the old metal gas pipes along the High Street in Brentwood from 15 September 2025 for six weeks until 27 October 2025.

08 September 2025

These works will take place from 9 September until 8 November 2025.

04 September 2025

Cadent will begin essential work on 26 August to upgrade nearly a kilometre of gas pipeline along Birkenhead Road in Meols, Wirral.

22 August 2025

This pioneering project will see gas distribution networks (GDNs) Cadent, SGN, Wales & West Utilities and Gas Networks Ireland work with innovators Bohr, Renda and Thyson Technology.

20 August 2025

Bracebridge Heath: details of project to upgrade 3100 metres of ageing gas main under Cross O’Cliff Hill and surrounding area

18 August 2025

Emergency road closure – Moreton Road, Upton, Wirral, and impacting M53 junction 2A

15 August 2025

Cadent selects Picarro Network Intelligence solution to Reduce Methane Emissions and Enhance Safety and Operational Efficiency

13 August 2025

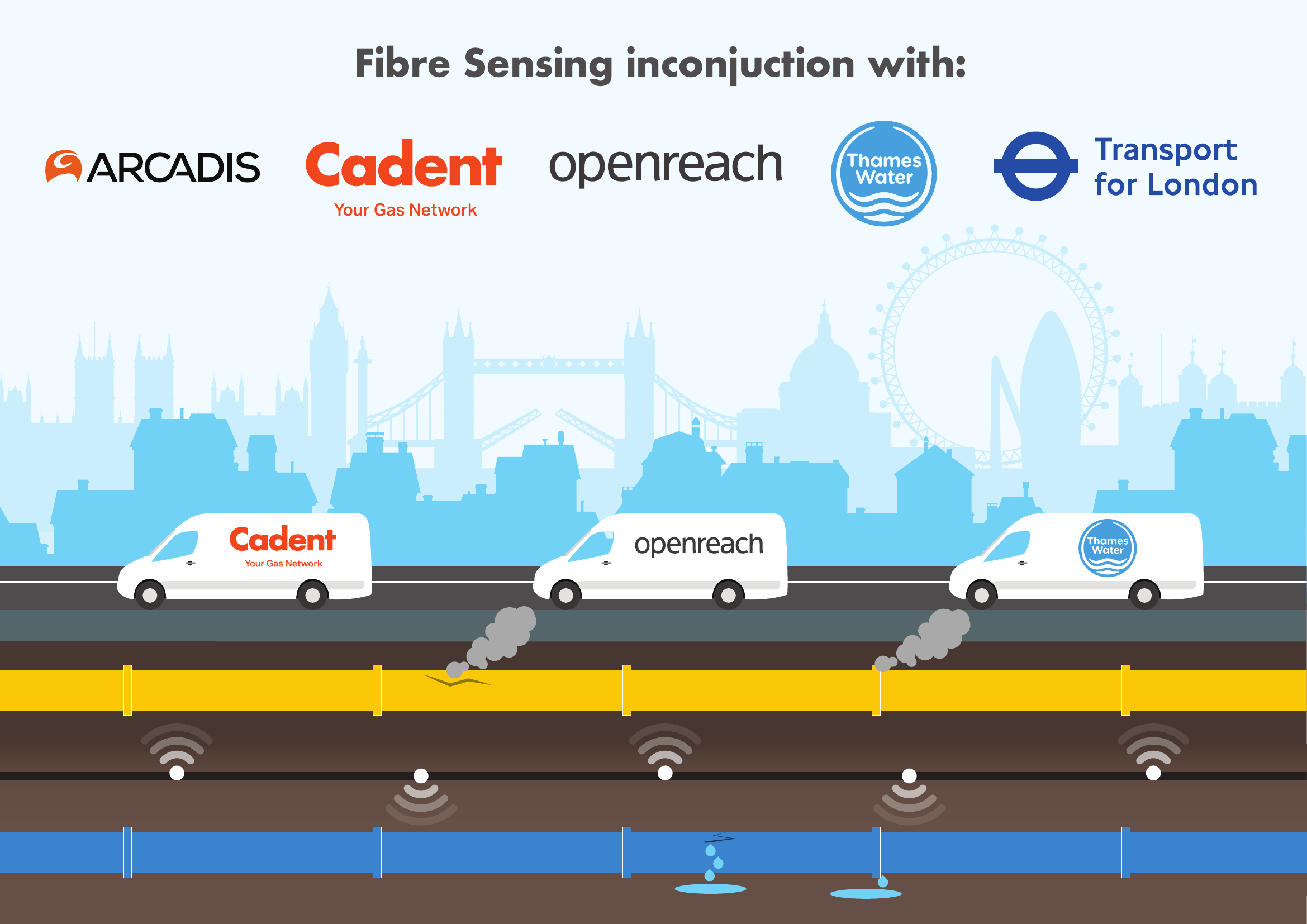

A partnership between Arcadis, Thames Water, Cadent, and Openreach, is trialling the use of the latest fibre optic sensing technology to detect and prevent costly and disruptive water and gas leaks.

11 August 2025

Cadent, the UK’s largest gas distribution network, has today announced the appointment of John Holland-Kaye as non-Executive Chair of its Board

07 August 2025

Public event taking place on Monday 18 August

05 August 2025

Cadent to replace 1500 metres of gas mains in Bury St Edmunds

01 August 2025.jpg?language=en)

Ulverston: major engineering project to safeguard gas supply for thousands remains on track

25 July 2025

A project to upgrade over five kilometres of gas main pipeline in Kessingland got underway earlier this week.

25 July 2025

Essential work in Urmston will help keep residents connected to safe and reliable gas supplies for heating and cooking.

22 July 2025

The event is for residents and businesses to learn more about essential work to upgrade almost one kilometre of gas pipeline in Ware, which will begin on Monday 4 August.

22 July 2025

We are working to restore gas supplies after a Thames Water main burst and water got into the local gas network in the TW10 area of Richmond Hill on Sunday evening, 20 July 2025.

21 July 2025

We established there was a burst water main in the area and that we have water in gas pipes. We have mobilised significant resources to deal with this.

21 July 2025

Essential work in Glemsford will help keep residents connected to safe and reliable gas supplies for cooking and heating

17 July 2025

Cadent and Italgas reaffirm their strategic cooperation today: the two companies have renewed the Memorandum of Understanding (MoU) signed in 2023

17 July 2025

Major works to replace 500 metres of gas pipes under West Road (and surrounding areas) in Bourne

17 July 2025

Work is set to begin on Thursday 17 July to replace ageing gas pipes in Poynters Road and Brunel Road, Luton

16 July 2025

Essential work to upgrade almost two kilometres of gas pipeline in Peterborough will begin on Monday 28 July in Reeves Way.

16 July 2025

Essential work in Hitchin will help keep residents connected to safe and reliable gas supplies for cooking and heating, Upgrade planned to coincide with the school summer holidays.

16 July 2025

Essential work in Great Amwell will help keep residents connected to safe and reliable gas supplies for cooking and heating

14 July 2025

The planned activity will involve installing 260 metres of tough new pipes which will last for decades, future-proofing the Colney Heath network.

11 July 2025

Summer upgrade for ageing Hemel Hempstead gas mains

10 July 2025

The work will take place over the school holidays to minimise disruption and is expected to last four weeks.

10 July 2025

Cadent and GRDF sign agreement of collaboration

08 July 2025

Essential Cambridge gas mains replacement work starts in July

27 June 2025

Lower Nazeing gas mains replacement work starts next week

12 June 2025

Heckington: details of project to upgrade ageing gas mains under Station Road, Heckington

10 June 2025

Big new mural transforms once-vandalised gas kiosk and pays homage to the RSPB

06 June 2025

Cadent’s response to Ofgem standards of service investigation conclusion

30 May 2025

Emergency gas works in Dinting Vale, Glossop

03 May 2025

385km of gas mains pipes will be upgraded this year in the North West

29 April 2025

Cadent, the UK’s largest gas distribution network, has announced the opening of its 350th Centre for Warmth.

27 March 2025

Cadent is replacing 2.5km of gas pipes along the B1310 - Aldermans Hill, Main Road and Southend Road, Hockley from 24 March to 12 December 2025.

21 March 2025

Fulbourn gas mains replacement work starts next week

12 March 2025

Mellor, Stockport update: upgrade for old gas pipeline to keep thousands warm for years to come

06 March 2025

cadent-fund-to-support-alzheimer-society

01 March 2025

Engineers working hard to resolve low gas pressure in Gamlingay

19 February 2025

Modernising gas pipes that have been in operation for decades;

03 February 2025

Bury Lane, Withnell: Upgrading old gas pipe to keep residents warm now and into the future

27 January 2025

Essential Cadent maintenance work in Enfield set for February

24 January 2025

High Peak: upgrade for gas main under Peak Forest Tramway Trail

16 January 2025

Mayor of Cambridgeshire and Peterborough visits Cadent apprentices

15 January 2025

Birkenhead: essential work on pipeline near Queensway Tunnel

10 January 2025

Warrington: how a new ‘Centre for Warmth’ partnership is helping thousands of people through challenging times

09 January 2025

Upgrading aging gas pipes

31 December 2024

Upgrading the aging gas mains in Sloane Square

27 December 2024

Cadent teams up with Cambridgeshire ACRE to help support rural community hubs

20 December 2024

Cadent publishes its RIIO-3 Business Plan

18 December 2024

It’s good to talk - North London team use Valve Trak trial to start conversations

13 December 2024

Cadent submits its RIIO-3 Business Plan to Ofgem

11 December 2024

Boston: details of project to upgrade 250 metres of ageing gas main under Strait Bargate, Boston

10 December 2024

A special Cadent podcast series on Grief

02 December 2024

Mellor, Stockport: upgrade for old gas pipeline relied on by thousands for warmth in winter

14 November 2024

Stockport: emergency gas work in Corporation Street

08 November 2024

Cadent teams up with Royal British Legion to support Armed Forces community

06 November 2024

Leicestershire: £200,000 upgrade for ageing gas pipes under Dodwells Island

05 November 2024

A long-serving community centre in Norwich, which was on the brink of closure just eight months ago, is now preparing to hold one of its biggest events to showcase its fantastic work.

31 October 2024

Work is set to begin on Monday 28 October to replace 1300m of ageing gas pipes in Stowmarket

24 October 2024

Our emergency engineers attended a report of a fire/explosion at 8:02am on Saturday morning (19/10/2024) on Cleat Hill, Bedford.

20 October 2024

The Hidden Dangers of Stealing Gas - It costs you and it costs lives

15 October 2024

Work will begin late on Friday 18th October, with a road closure (one-way).

14 October 2024

Launch of DAWS - Partnership Announcement

26 September 2024

One of Stockport’s oldest working gas pipes – at 145 years old – is being replaced

12 September 2024

Today we are delighted to host our second Global Technology Conference following the great success from last year.

11 September 2024

Cadent warns people are not regularly servicing gas appliances due to ongoing cost of living impact

11 September 2024

Braughing residents and businesses invited to learn more about upcoming gas pipe reinforcement work

10 September 2024

Water Ingress - Eton High Street

04 September 2024

Major works to replace 1,000 metres of gas pipes under Newark Road, Lincoln.

03 September 2024

A590 Swarthmoor: upgrade for old gas pipeline relied on by thousands for warmth in winter

02 September 2024

Safety equipment being stolen from gas work sites

02 August 2024

Work expected to be completed by early September

29 July 2024

Ipswich gas pipe replacement work starts this week

29 July 2024

Oldham: summer upgrade for town centre gas pipe to help with warmth in winter

22 July 2024

Altrincham: upgrade for old gas pipelines relied on by thousands for warmth in winter

19 July 2024

Second stage of Newport main replacement work gets underway

17 July 2024

Northwich: emergency works to repair gas pipe under A556

16 July 2024

Northwich: emergency closure of London Road due to gas escape

11 July 2024

Work started last week (Wednesday 3 July) and will last for around 10 weeks

09 July 2024

Work is set to begin on Monday 22 July

08 July 2024

Works will start on 22 July for 20 weeks

03 July 2024

Chester - loss of gas

29 June 2024

Work starts on 8th July and will take 15 weeks

26 June 2024

Grahame Park, Barnet – Water Ingress

21 June 2024

Gas mains upgraded in Newark Road Lincoln

12 June 2024

Crosby: emergency works start tomorrow (Saturday) to repair a gas pipe

07 June 2024

Traffic News – Road closure of Cockspur Street, London

04 June 2024

Water in gas pipes - Basford, Nottingham

02 June 2024

Upgrading gas pipes along Harrow View, Harrow

31 May 2024

Cadent Releases Annual Sustainability Report

28 May 2024

Mains Replacement Work starts Monday 20 May in Newport, Saffron Walden

17 May 2024

420,000 metres of pipe to be upgraded this year

30 April 2024

Work starts 7th May and continues to July

29 April 2024

Loss of Gas

26 April 2024

Essential work to the local gas network

16 April 2024Sun, Sea and Centres for Warmth

25 March 2024

Kings Road works should complete during March

18 March 2024

Next stages of Benfleet and Canvey Island project to start

18 March 2024

Exploring the regional potential for storage options

08 March 2024

Cadent releases Annual Gender and Ethnicity Pay Gap Report

07 March 2024

Work is set to start 11 March

05 March 2024

New 'governor' is being installed below ground

04 March 2024

Handing off to Shannon

25 February 2024.jpg?language=en)

A public commitment to delivery of net zero ambitions

16 February 2024

Maldon gas mains replacement work starts next week

16 February 2024

Luton: Emergency gas main replacement

15 February 2024

Harborne, Birmingham: update on gas repair and traffic management

10 February 2024

Final phases of major repair works

03 February 2024.png?language=en)

Cadent Foundation and Groundwork to distribute 5,000 Winter Warmer Packs to help households tackle the cold

02 February 2024

200th 'Centre for Warmth’ opens as freezing temperatures grip the UK

26 January 2024

Special Minecraft game helps build roadwork safety

19 January 2024

UK's poorest faced with stark choices amid extreme weather conditions

19 January 2024

A road closure from Monday 22 January

19 January 2024

Lincoln: extension of project to upgrade 800 metres of ageing gas main under Newark Road

16 January 2024

One of the biggest pipes in the North West network

10 January 2024

Engineers repairing the local gas network

09 January 2024

Maida Vale, London - Evacuation

05 January 2024

Newham – Road closure for essential repair - CISBOT used for repair

04 January 2024

Statement: Smell of gas in Colchester

04 January 2024

Updated Statement: Widnes loss of Gas

02 January 2024

Media Statement: Explosion, Bradley in the Moors

29 December 2023

Santa and his reindeer aren’t the only ones working this Christmas!

24 December 2023

Final phase starts early January 2024

21 December 2023

End is in sight for Woodbridge mains replacement

19 December 2023

Bedford mains reinforcement and replacement work to start in new year

18 December 2023

Emergency road closures announced for Woodbridge gas mains upgrade work

12 December 2023

Details of temporary traffic arrangements

12 December 2023

Cadent answer BBC's DIY SOS call

11 December 2023

Cadent collects gold award

04 December 2023_1.jpg?language=en)

Do students know the difference between freshers flu and CO poisoning?

29 November 2023

A statement from Great Britain's gas networks

27 November 2023

Gas emergency work Farringdon Road, London

27 November 2023

Beware of bogus workmen

24 November 2023

Eccles: essential work to repair a gas pipeline deep underground

17 November 2023

Cadent awarded Sustainability ‘Sector Leader’ status

16 November 2023

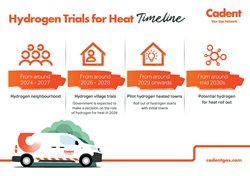

Pioneering Hydrogen programme to bring low carbon energy benefits for the North-East, Midlands and beyond

13 November 2023

The work is happening in Arrowe Brook Road

10 November 2023

Essential Woodbridge gas mains upgrade to begin next week

09 November 2023

Remembrance Day 2023: Zoe's career in the Navy

08 November 2023

Cadent appoints utility industry stalwart as Chair of newly launched Customer Challenge Group

07 November 2023

Gas repair work underway on Bedford footpath

03 November 2023

Essential Manchester gas main upgrade to begin next week

01 November 2023

Work takes place until December

27 October 2023

Work should be complete by January 2024

26 October 2023Cadent Raises £40,000 to Support local community centre

26 October 2023

Cadent engineers volunteer to refresh Bedfordshire benches

20 October 2023

Ipswich gas repair work starts today

10 October 2023

Cadent engineers volunteer to help Norfolk residents feel safe at home

26 September 2023

Wellingborough: details of joint project between Cadent

25 September 2023

Large gas escape - Fordham, Ely, Cambridgeshire

25 September 2023

Cost of Living Crisis impacting UK’s ability to hit Net Zero targets

20 September 2023

Cadent issues safety warning after boiler tampering to save money

07 September 2023

Marple, Stockport: Emergency Road Closure

05 September 2023

Lowestoft mains reinforcement work starts on Monday

01 September 2023

Leak will be closely monitored all weekend

31 August 2023

Introducing the new Warm Homes Network

30 August 2023

Lane closure – Gatley Road, Cheadle

10 August 2023

Explosion in Battersea - not gas related

10 August 2023

Road closure - Midland Road, Bedford

02 August 2023

Work starts 31st July, for around 20 weeks

28 July 2023

Work starts 31st July

27 July 2023

A new partnership to deliver vital safeguarding training

27 July 2023.jpeg?language=en)

Trafalgar Square gas mains repair

17 July 2023

50% of project now complete

12 July 2023

Major project to carry out essential repairs

12 July 2023

Hydrogen Village Statement

11 July 2023

Bristol Gardens, W9 London, mains replacement project

10 July 2023

St Albans: loss of gas to properties in Park Street area

29 June 2023

We're funding a new 'Safe and Well Communities Project' with the YMCA

28 June 2023

Work starts 24th July, for around six weeks

19 June 2023

Lorna Millington awarded MBE for her work in Business and Environment

16 June 2023

#Imagine 2033

13 June 2023

Supplying energy to over 10,000 homes

02 June 2023

Work starts Tuesday 30th May

26 May 2023

Temporary road closure in the town centre

11 May 2023

Photos show impressive engineering onsite

10 May 2023

2023 will go down as a moment in history for Britain.

05 May 2023

Important new guidance launched ahead of Spring renovation season

05 May 2023

Cadent has been awarded the Menopause Friendly Accreditation

05 May 2023

Be aware of the dangers of carbon monoxide… or it could be game over.

03 May 2023

Details of 2023-24 gas mains upgrade programme

27 April 2023

Work is due to begin 24th April 2023

14 April 2023

Gas leak calls for urgent mains replacement work on Bridge St, Bridg

06 April 2023

Empowering young people to make sustainable and cost-effective choices

04 April 2023

Cadent announces major investment in Leamington Spa gas network

31 March 2023

Keeping everyone safe

31 March 2023

Benfleet - 2nd phase of major investment starts

31 March 2023

Dedicated policy to support fertility treatment

30 March 2023.jpg?language=en)

Creation of 'Hydrogen Valley' could bring jobs to WM & EoE

29 March 2023

Whitby residents revised offer for Hydrogen Village trial

29 March 2023

Working to support adult carers and their families

28 March 2023

Teams will be working round-the clock, 24 hrs

28 March 2023

Our sense of smell plays an essential role in keeping us safe

21 March 2023

New website launched to help customers sign up to the PSR

20 March 2023

Educating young people about the dangers of carbon monoxide

14 March 2023

Cadent working to reopen Ashworth Lane asap

11 March 2023

Cadent releases Annual Gender and Ethnicity Pay Gap Report for the first time

02 March 2023

Helping our customers live independently and safely in their own homes

01 March 2023

Photo shows the challenge facing engineers

01 March 2023

2,000 metres of new gas pipes

23 February 2023

We need to resolve issue with gas pipe

20 February 2023

Half of UK consumers feel powerless to reduce energy bills

20 February 2023

Benfleet and Canvey Island: investing in the local gas pipe network

16 February 2023.jpeg?language=en)

National Apprenticeship Week

10 February 2023

We're working towards zero waste to landfill

24 January 2023

Cadent submits proposal to Government for Hydrogen Towns

23 January 2023

Low carbon hydrogen is a new home-grown super-fuel

19 January 2023

CISBOT deployed for its latest North West job

09 January 2023

Keeping everyone safe and warm in their homes

06 January 2023

Work starts on Saturday 7 January and will take place on 7/8 and 14/15

05 January 2023