History - Hammersmith Bridge was closed in 2019 due to the integrity of the foundations of the bridge.

Cadent own and maintain the gas network in the area and have two pipes on the bridge, which supply gas to homes and businesses in Barnes, Mortlake and Putney. We have been requested to decommission both gas pipes on Hammersmith Bridge.

The project - Lay a new gas pipe before diverting the gas from the two pipes on Hammersmith Bridge, ensuring the gas supply to the local area is maintained at all times.

Start date - 6 March 2023 for 12-14 months, to lay 2.5km (1.6 miles) of a new gas pipe. Once this is completed, we will divert the gas from the two gas pipes on the bridge into the new pipe.

Gas supplies will not be interrupted.

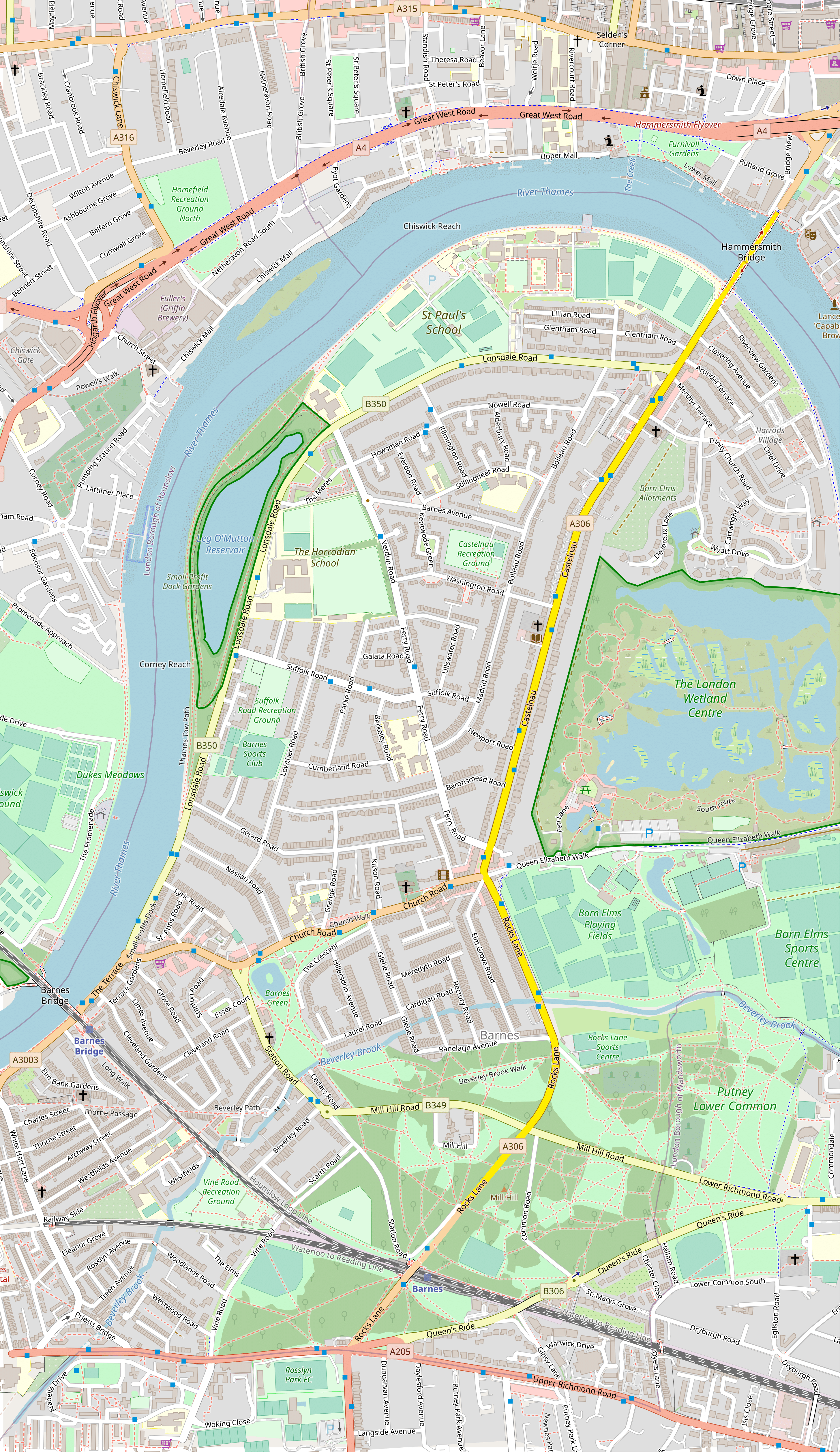

The new gas pipe will laid from the junction of Station Road / Rocks Lane onto Castelnau.

.jpg?width=150&height=223)

We have won the Green Apple Environment Awards in 2023 for this project's innovation to reduce emissions for the diversion project.

WHAT ARE THE GREEN APPLE AWARDS?

The Green Apple Environment Awards were established in 1994 as an annual campaign to recognise, reward and promote environmental best practice around the world.

The Green Apple Awards scheme was the first to be accredited as an official feeder scheme into the European Business Awards for the Environment and it is now the only official feeder scheme into the Green World Awards, which are held in a different country every year.

Previous Green Apple Award winners have gone on to win European and World Awards, and many have taken on the status of International Green World Ambassadors by helping others around the world to help the environment.

Cadent's submission

A partnership between Cadent, Morrison Energy Services Ltd and Terrafirma Pipeline Ltd were commissioned to undertake a gas main reinforcement project within the London Borough of Richmond upon Thames.

The project aim was to lay approximately 2.5km of new medium pressure gas main to help reinforcement the gas network and provide a sustainable and secure supply of gas to residents and the local community whilst implementing improvements and initiatives to reduce the environmental and social impact of the project.

Project Achievements

During the first three months the innovative solutions have seen (compared to baseline):

- 5,500 kg CO2e reduction in project emissions.

- 66% reduction in fuel consumption.

- Significant reduction in noise compared to business as usual utility projects and improvement in operational staff’s mental wellbeing.

- Improved security and stability of gas supply to customers.

- Improved relationship with local authority and stakeholders following operational teams performance and implementation of initiatives.

Diverting the gas supply from Hammersmith Bridge by laying 2.5km of a new medium pressure gas pipe.

A different mindset

Awareness - It started with our colleagues. Having identified the potential impact the project could have on local wildlife and community, the team created a detailed briefing for the site team.

Briefings were given to the team to improve their understanding of the local environmental hazards, including Barnes Common Nature Reserve, bats, nesting birds and water voles; and reiterating the procedures in place, should they encounter protected species.

During construction - It was also established that a design change could reduce the environmental impact of the project.

Instead of crossing Beverley Brook with the new gas main and removing ten mature trees and disturbing the riverbanks which had potential water vole habitats; we collaborated with the council and completed trial holes on the existing bridge structure.

The trial holes were successful and the design was changed to a new four-tier manifold system. This meant the new gas main could be placed within the road, removing the need for tree felling and disturbance to the watercourse.

A platform to deliver more sustainable projects

We are hoping to use the Hammersmith Bridge project as a platform to deliver more sustainable utility projects across our North London network.

The transition to HVO fuel was a major success on the project. The initiative provided zero logistical issues whilst providing 90% reduction in fuel emissions. As well as providing environmental benefits, the operational team commented on how impressed they were with the near silent-running welfare unit team as they felt the unit really enhanced their ‘working conditions’. They were able to have meetings and breaks in a modern, hygienic, and quiet welfare unit without the drone of a diesel generator.

Due to the success of the HVO fuel, welfare unit and project in general, we have already been having discussions with stakeholders to deliver another low-emissions project at Parliament Hill, Camden over the next 12 months. We have committed to phasing out all diesel generator welfare units across their multi-occupancy buildings workstream in London and had the first unit delivered in June 2023!

In April 2023, we launched our ‘North London Environmental Action Plan’ along with our partners Morrisons, which explores a variety of channels to enhance sustainability and drive us towards our net zero ambitions.